Employee introduction07 Searched for a new job in the electronics industry. Brings a quality assurance perspective to the development process

S.K.

Joined as mid-career hire in 2023

CS DivisionQuality Assurance Dept., Toyama Automotive Quality Assurance Sec.Quality assurance

Background

What sort of job did you have before you joined SMK?

Previously, I did quality control and quality assurance at an electronic components maker. I experienced quality improvement activities for manufactured products and customer service. I was also involved with internal quality audits and acquiring external certification. I worked to strengthen manufacturing systems by improving and establishing QMS (Quality Management System).

Why did you change jobs, and what made you choose SMK?

At my last company, I was transferred out of my prefecture. As I needed to return home due to household circumstances, I made up my mind to quit the role and find a new one near my home.

As a student, I was not particular about which industry to work in. The key points of my job search were that the business would let me grow, and that it was a manufacturer in Toyama that did business with global partners, so I took a position with an electronics maker in Toyama Prefecture. When it came to finding the next job, I narrowed it down to companies in the same industry but my other conditions were unchanged.

SMK is one Toyama electronics maker that does business around the world. I was also impressed by the human resources system, the staff benefits, pleasant working environment and expectations for individual growth. Feeling that this was a company in which I could make use of my previous experience, find personal growth and contribute to the business, I made the decision to take this job.

Work

Compared to your last company, how is the ease of working here?

At SMK, a team is formed for each new product with a member from each department. The team handles everything from development to post-mass production improvement activities. As the member of the team responsible for quality assurance, I have a wide range of quality control and quality assurance tasks, rather than one particular job. I feel that SMK has an environment that allows you to get more experience. And my image of SMK emphasizing cross-departmental collaboration for task efficiency and improved productivity in the organization as a whole has proven to be true.

Tell us about your job.

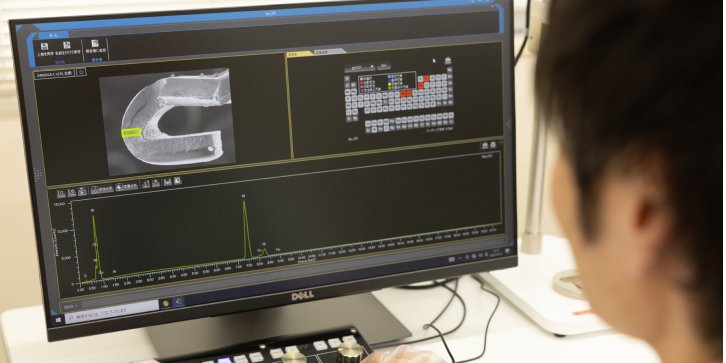

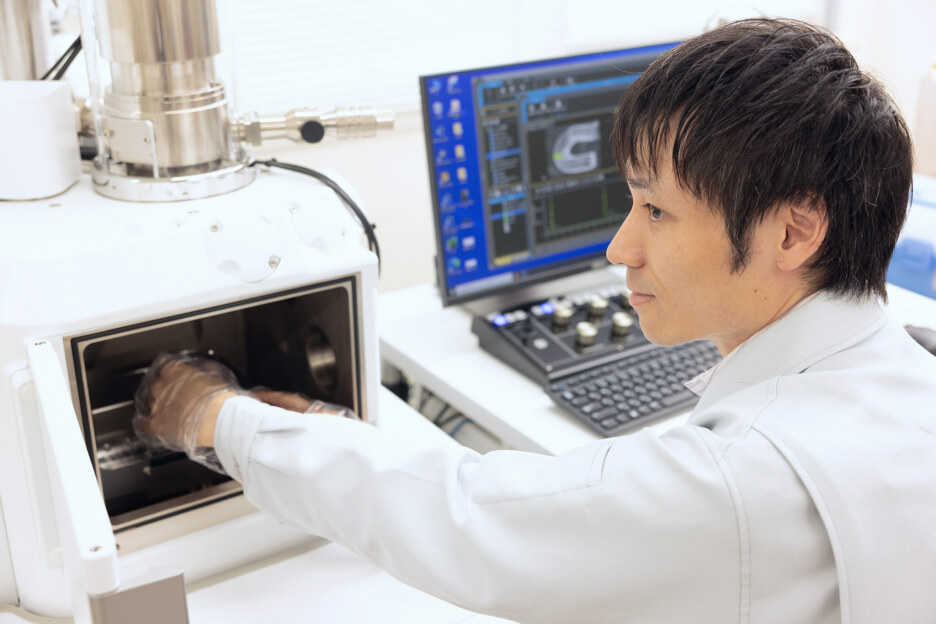

I do quality assurance for the products I am charge of from development to the mass production phase. In product development, I engage in work from the standpoint of quality assurance in order to prevent defects at the product design and process design stage that would upset customers. For example, we discuss the control points that a product needs, based on customer demands and examples of previous defects, then integrate them into the process. In either role, I am working to improve quality in consultation with other departments and sometimes, with suppliers too.

Tell us about a job that made the deepest impression on you.

It was the development of connectors for e-bikes when I was first appointed to take charge of quality assurance for a development project that has stayed in my mind.

This was my first time to be involved in a development project, something that never happened at my last company. In the beginning, I knew nothing. But with the support of my boss and colleagues from other departments, I made progress as a project member. Gradually, the product began to take shape in the lead-up to mass production. It was very satisfying to see a development product I was involved in pass through the internal process of inspection and customer certification on its way to being rolled out around the world. As my first project it was special, and it was a great experience that showed me the difficulties of developing products and the rewards it offers.

Vision

Describe your dreams and goals.

Initially, my goal is to master all of my tasks related to the product we are developing as the Quality Assurance Dept. member. Some aspects of my thinking about quality assurance remain immature, so I will keep learning from my senior colleagues and put that into practice.

In future, it is my goal to become a team leader who contributes to everything from quality to the profit of the company. I want SMK to be very strong on quality as a result of our strengthened manufacturing, and development of skills of my colleagues who are making products.

CASUAL QUESTION

What do you do after work or on your days off?

When it comes to weekends and holidays, I veer between the great indoors and the great outdoors. When I don't feel like leaving home, I just curl up and play video games or watch movies. On the other hand, I am also an outdoors guy. I will take a trip every month and sometimes take in a concert. Whatever it is, doing something I love doing is most refreshing.

A day in my work life